Blogsheet week 7

1.

Force sensing resistor gives a resistance value

with respect to the force that is applied on it. Try different loads (Pinching,

squeezing with objects, etc.) and write down the resistance values. (EXPLAIN with

TABLE)

Fig 1.

We use various objects and pressures of fingers against the sensor. As you can see the more pressure that is placed against the sensor the less resistance we get.

Resistance

(Ω)

|

Object

|

4.6k

|

Coffee mug on edge

|

12.2k

|

Keys

|

2k

|

Index finger resting

|

208.6

|

Index finger pressing

|

78.3

|

Thumb pressing

|

We use various objects and pressures of fingers against the sensor. As you can see the more pressure that is placed against the sensor the less resistance we get.

2.

7 Segment display:

a.

Check the manual of 7 segment display. Pdf

document’s page 5 (or in the document page 4) circuit B is the one we have.

Connect pin 3 or pin 14 to 5 V. Connect a 330 Ω resistor to pin 1. Other end of

the resistor goes to ground. Which line lit up? Using package dimensions and

function for B (page 4 in pdf), explain the operation of the 7 segment display

by lighting up different segments. (EXPLAIN with VIDEO).

A video showing us connecting inputs to different segments of the 7 segment display.

b.

Using resistors for each segment, make the

display show 0 and 5. (EXPLAIN with PHOTOs)

|

| A picture showing the 7 segment display with 0 displayed. |

|

| A picture showing the 7 segment display with 5 displayed. |

3.

Display driver (7447). This integrated circuit

(IC) is designed to drive 7 segment display through resistors. Check the data

sheet. A, B, C, and D are binary inputs. Pins 9 through 15 are outputs that go

to the display. Pin 8 is ground and pin 16 is 5 V.

a.

By connecting inputs either 0 V or 5 V, check

the output voltages of the driver. Explain how the inputs and outputs are

related. Provide two different input combinations. (EXPLAIN with PHOTOs and TRUTH TABLE)

For example if we wanted to display the numbers 0, 4, or 5 these would be the inputs for the display driver:

This is the truth table that relates the inputs of the 7447 to the outputs which would be connected to the 7 segment display

For example if we wanted to display the numbers 0, 4, or 5 these would be the inputs for the display driver:

|

| Desired inputs for 0, 4, or 5. |

|

| Truth table for the Display Driver |

|

| The output to the LED in this picture is 0. |

|

The output to the LED in this picture is 1.

|

b.

Connect the display driver to the 7 segment

display. 330 Ω resistors need to be used between the display driver outputs and

the display (a total of 7 resistors). Verify your question 3a outputs with

those input combinations. (EXPLAIN with VIDEO)

A video showing us getting different results with different inputs.

4.

555 Timer:

a.

Construct the circuit in Fig. 14 of the 555

timer data sheet. VCC = 5V. No RL (no connection to pin

3). RA = 150 kΩ, RB = 300 kΩ, and C = 1 µF (smaller sized

capacitor). 0.01 µF capacitor is somewhat larger in size. Observe your output voltage

at pin 3 by oscilloscope. (Breadboard and Oscilloscope PHOTOs)

|

| A picture showing our breadboard setup of the 555 timer. |

|

| A picture showing the output of pin 3 by the 555 timer. |

b.

Does your frequency and duty cycle match with

the theoretical value? Explain your work.

Our theoretical is frequency is 1.92 Hz and the theoretical duty cycle is 0.4. As you can find from our oscilloscope picture in the previous part, the frequency we measured is 1.62 Hz and the duty cycle was around 0.4.

|

| Duty Cycle calculation |

| Frequency calculation |

c.

Connect the force sensing resistor in series

with RA. How can you make the circuit give an output? Can the

frequency of the output be modified with the force sensing resistor? (Explain with VIDEO)

A video showing our force sensing resistor giving an output while connected to the 555 time. Varying pressures give different frequencies.

5. Binary coded decimal (BCD) counter (74192). This circuit generates a 4-bit counter. With every clock change, output increases; 0000, 0001, 0010, …, 0111, 1000, 1001. But after 1001 (which is decimal 9), it goes back to 0000. That way, in decimal, it counts from 0 to 9. Outputs of 74192 are labelled as QA (Least significant bit), QB, QC, and QD (Most significant bit) in the data sheet (decimal counter, 74192). Use the following connections:

5. Binary coded decimal (BCD) counter (74192). This circuit generates a 4-bit counter. With every clock change, output increases; 0000, 0001, 0010, …, 0111, 1000, 1001. But after 1001 (which is decimal 9), it goes back to 0000. That way, in decimal, it counts from 0 to 9. Outputs of 74192 are labelled as QA (Least significant bit), QB, QC, and QD (Most significant bit) in the data sheet (decimal counter, 74192). Use the following connections:

5 V: pins 4, 11, 16.

0 V (ground): pins 8, 14.

10 µF capacitor between 5 V and ground.

a.

Connect your 555 timer output to pin 5 of 74192.

Observe the input and each output on the oscilloscope. (EXPLAIN with VIDEO and TRUTH TABLE)

A video showing the output of the counter on the oscilloscope.

6.

7486 (XOR gate). Pin diagram of the circuit is

given in the logic gates pin diagram pdf file. Ground pin is 7. Pin 14 will be

connected to 5 V. There are 4 XOR gates. Pins are numbered. Connect a 330 Ω

resistor at the output of one of the XOR gates.

a.

Put an LED in series to the resistor. Negative

end of the LED (shorter wire) should be connected to the ground. By choosing

different input combinations (DC 0V and DC 5 V), prove XOR operation through

LED. (EXPLAIN

with VIDEO)

A video showing the operation of the XOR gate.

b.

Connect XOR’s inputs to the BCD counters C and D

outputs. Explain your observation. (EXPLAIN with VIDEO)

A video showing the output of the C and D outputs connected to the XOR gate.

c.

For 6b, draw the following signals together: 555

timer (clock), A, B, C, and D outputs of 74192, and the XOR output. (EXPLAIN with VIDEO)

|

| The 555 timer, A, B, C, and D outputs of 74192, and the XOR output signals drawn together. |

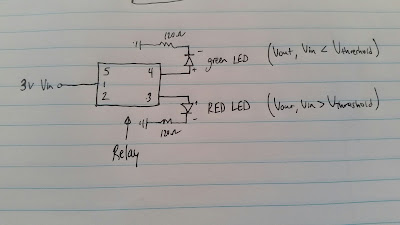

7.

Connect the entire circuit: Force sensing resistor

triggers the 555 timer. 555 timer’s output is used as clock for the counter.

Counter is then connected to the driver (Counter’s A, B, C, D to driver’s A, B,

C, D). Driver is connected to the display through resistors. XOR gate is

connected to the counter’s C and D inputs as well and an LED with a resistor is

connected to the XOR output. Draw the circuit schematic. (VIDEO and PHOTO)

|

| A picture of our entire circuit. |

|

| A drawing of our circuit schematic. |

A video showing the operation of our entire circuit

8.

Using other logic gates provided (AND and OR),

come up with a different LED lighting scheme. (EXPLAIN with VIDEO)

A video showing the operation of our entire circuit with an added output.